How Conway Concrete Company Concreters can Save You Time, Stress, and Money.

Wiki Article

The 15-Second Trick For Conway Concrete Company Concrete Contractor

Table of ContentsHow Conway Concrete Company Concrete Contractor can Save You Time, Stress, and Money.Conway Concrete Company Conway Arkansas for BeginnersConcrete Contractor Can Be Fun For Anyone7 Easy Facts About Conway Concrete Company Concreters Explained

As you shop, you'll find that there are three typical concrete types available, including Portland cement, masonry concrete and also mortar mix. Rose City Cement: Rose City concrete is a material frequently made use of to produce concrete. It acts similar to a strong glue, offering a dependable bond that makes it a popular selection for laying driveways and paths.Masonry Concrete Mix: Structure brick or rock frameworks needs the commercial-grade toughness of masonry concrete mix.: Mortar is a common concrete mix made use of to lay brick as well as rock.

Concrete is among the most necessary building materials as well as is typically made use of in sidewalks, foundations, roads, bridges, walls, fences, as well as posts. By solidifying and solidifying after blending with water, concrete assists bind (highly) various other structure products. With several sorts of concrete to pick from, it is crucial to understand which one finest fits the construction you are functioning on.

Ready? Then let us get right to company. Concrete is a crucial building and construction material utilized thoroughly in tiny, medium, or big building and constructions. As a composite material, concrete is composed mostly of water, cement, as well as accumulation (sand, crushed rock, or rock). When the above materials are mixed in good proportions, they normally form a stone-like paste that has a tendency to set in time, holding different parts of a structure.

Some Known Details About Conway Concrete Company Concreters

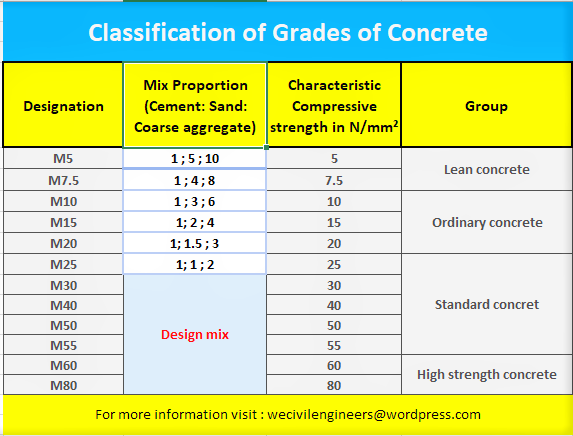

The value of mixing concrete, water, and also accumulations in great proportions can not be overemphasized. This is because the proportion of parts made use of in making concrete determines its stamina, workability, resistance to components, and also toughness. Generally, concrete as well as lime are normally used as the binding materials, while sand acts as the fine aggregate (Conway Concrete Company concreters).

As technical improvements continue to influence building and construction techniques and treatments, so too does concrete evolve. Concrete category is normally based upon three elements:,, and also the. Below is an in-depth conversation of the primary kinds of concrete used in building. Simple concrete is amongst the most generally made use of concrete and is a wonderful selection for pavements or various other locations that do not need incredibly high tensile stamina.

Although ordinary concrete has an adequate durability ranking, it is not known to stand too well to wind loading and also vibrations, hence its usage for light to medium construction. Concrete that has a thickness of anything below 1920 Kg/m3 is identified as light-weight concrete. This kind of concrete is understood for its reduced thermal conductivity, that makes it wonderful for protecting exposed steel structures.

The most typically utilized aggregates in light-weight concrete consist of scoria, pumice, perlite, vermiculite, clays, as well as expanded shales. Called heavyweight concrete, high-density concrete has the highest thickness of all kinds of concrete.

Fascination About Conway Concrete Company Concrete Slab

Due to its thickness as well as strength, high-density concrete is mostly made use of in large frameworks like atomic plants that generate possibly hazardous radiations. The high-density concrete material will avoid the radiations from passing via the wall surfaces.

Recognized as enhanced cement concrete (RCC), this kind of concrete typically features different-sized steel that acts as a support to boost the total tensile toughness. In strengthened concrete, cords, cords, as well as steel poles are normally positioned prior to the concrete collections.

An effective bond in between concrete as well as the steel supports enables the resulting strengthened cement concrete to bear various sorts of tension and also lots in tiny, medium, as well as hefty constructions. This makes RCC amongst one of the most crucial concrete kinds, particularly since it can be used in a wide array of tasks without endangering on structural stability.

Precast concrete is commonly made use of in jobs that require healthy proportions for the concrete to hold various other members in place. And to raise the concrete's efficiency throughout building, precast concrete is normally made in manufacturing facilities with much attention offered to the proportioning of the primary active ingredients of concrete. visit this web-site Consequently, by the time the concrete gets here on site, the cement, water, prefabricated concrete homes designs and also aggregates are usually properly combined to suit the precise building and construction needs.

The Definitive Guide for Conway Concrete Company Concreters

The main advantage of using this type of concrete is the fast on-site setting up.

Prestressed concrete jobs by combining the high compressive stamina of concrete as well as steel's high tensile strength. By prestressing the concrete prior to usage in building, construction designers are ensured that the concrete will certainly hold its weight well and as a result counteract the resulting pressures. Prestressed concrete is typically made use of in piles, floor light beams, water containers, bridges, paths, and train sleepers, among various other hefty types of building and construction.

The air bubbles perform the duty of creating expansion chambers to enable water to expand when freezing, as a result eliminating the concrete's internal pressure. To entrain the air, concrete professionals add lathering representatives like alcohols, fats, and also resins throughout the concrete blending process. For the task to be effective, engineering supervision is necessary to guarantee the air-entrained concrete is well combined.

Frameworks that make use of air-entrained concrete are extra resistant to degeneration resulting from cold and also thawing, scaling, and abrasion. Quick solidifying concrete, additionally referred to as rapid-set concrete, is excellent for tasks with short durations. This kind of concrete has a solid track record for establishing rapid and also is highly immune to reduced temperatures, that Full Report makes it optimal for usage any time, no matter the season.

Report this wiki page